Task Force Tips

Task Force Tips

Their short story

Task Force Tips is a manufacturer of firefighting equipment that wanted to promote and maximize their personnel tending machining cells into more complex tasks while keeping their spindle time up and product quality consistent.

The challenge faced

Task Force Tips in Indiana has integrated robots with machine tools as far back as 1990. Those robots however only worked on the machine they were installed with and could not be moved to other machines.

The company needed to adapt to the use of collaborative robots since they can be used in a much more flexible manner.

The solution

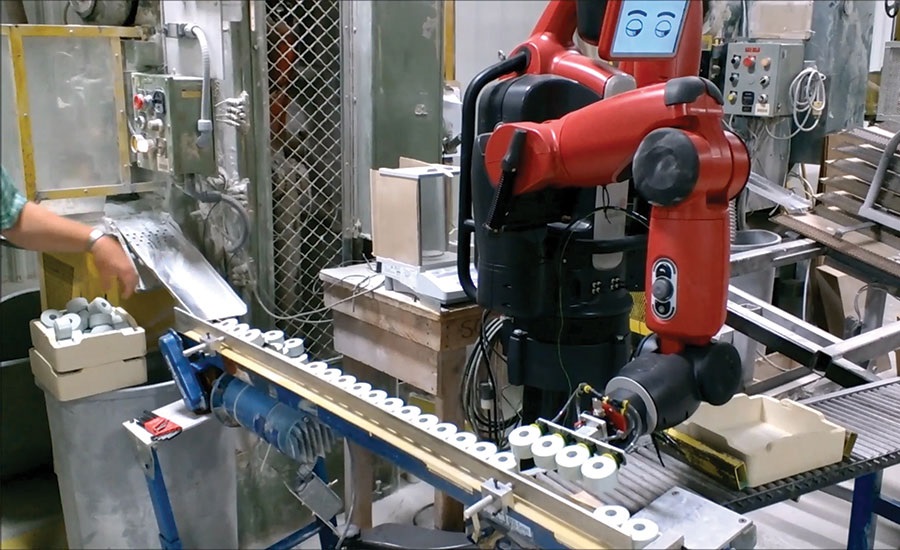

Task Force Tips installed one UR10 robot and two UR5 robots to tend their CNC machines and the fourth UR5 that was mounted onto a table on wheels and moved between tasks.

The UR robots have reduced their staffing requirements from seven to three operators since the major impediment in the past of using the traditional robots was the security fencing required around the machine. The best thing about the UR Robots is they do not need any guarding. Their staff can roll the table with the robot right up to the machine and in a few minutes teach the small industrial robot to load parts

Now it only takes them an hour per shift to operate the cobot, which includes laying out parts and staging the robot to efficiently running for 21 hours unassisted.

The work of the cobots

Having two UR5 cobots working in tandem have helped the manufacturer to optimize their production. As blanks arrive on the inbound conveyor, the first UR5 robot uses vision guidance to identify and pick up the blanks then inserts them into the first milling machine.

The UR5 cobot arm then takes out the half machined part already in the lathe and hands it over to the other UR5. The second cobot inserts that part into the second machine, takes out the complete machined part and places it on the outbound conveyor, where an operator places the parts onto anodizing racks which completes the cycle.

It is a process that looks very impressive, but was deceivingly easy to do considering that both the robot handoff and the vision guidance use the MODBUS communication protocol registers in the cobot’s controller from Universal Robots.

When the UR5 places the un-machined part in the lathe, the robot’s force detection will identify if the part has some burs from the saw cut or if there are machining chips in the chuck jaws.

When the robot tries to reach the set waypoint for placement and there is an obstruction that is causing the force on the end of arm to exceed 50 Newton which has been programmed as the threshold, it will detect that something is wrong.

The robot will go through the air blast several times and if it still cannot place the part, the cobot tells the machine to execute a “chuck wash” cycle, which uses the machine’s high pressure coolant system to dislodge debris from the chuck jaws. If the part still cannot load after the coolant wash, the popup appears on the cobot’s touchscreen, instructing the operator to clear any debris from the chuck jaws and press continue. If the issue persists, there is another popup that halts the program entirely. The operators can then diagnose the problem, fix it, and restart the production process.

Freeing up personnel from machine tending has also played an important role in increased product quality. When the employees are not worried about keeping a machine running all the time, they have plenty of time to visually inspect the machined products.

Part quality has really gone to a whole other level with the cobot in place as it also allows their personnel to come up with new ideas and better ways of improving their production.